News

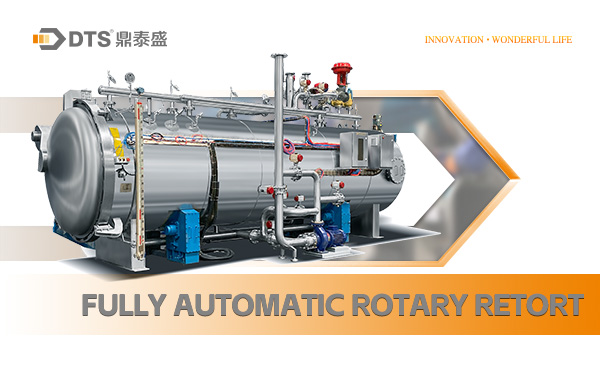

DTS automatic rotary retort suitable for soup cans with high viscosity, when sterilizing the cans in the rotating body driven by 360 ° rotation, so that the contents of the slow movement, improve the speed of heat penetration at the same time to achieve uniform heating and cooling, non-layered, no precipitation purpose. The adoption of frequency conversion speed control makes the equipment can be used for products with different viscosity, such as: instant meal, soup canned food, canned vegetables, pet food, etc.

Automatic rotary retort has the following product features:

1, Steam double valve design prevent the valve leakage over-temperature and result in product damage;

2, External drag wheel and cylinder support integrated, cylinder plus guard plate with small force, it has the advantage of wear resistance, maintenance is more convenient and quick;

3, The rotating body is molded by one-time processing, adopts forged rolling ring and the whole is processed by aging and vibration treatment, dynamic balancing treatment and other processes, which ensures the rotating concentricity, avoids the phenomenon of bias weight and prolongs the service life;

4, Positive pressure and negative pressure double safety protection to prevent equipment damage;

5, The use of alloy cylinders were automatically pressed to solve the spring reset is not allowed as well as the cylinder leakage and other shortcomings;

6, Brake reducer has automatic positioning function to ensure that the cage is in horizontal position after stopping, which is convenient for smooth docking with other supporting equipment.