News

With the continuous advancement of science and technology, the application of intelligence has become the mainstream trend of modern manufacturing industry. In the food industry, this trend is particularly obvious. As one of the core equipment in the food processing industry, the upgrading and application of the intelligent sterilization production system of the sterilizer is closely related to the high-quality and long-term development of food production enterprises.

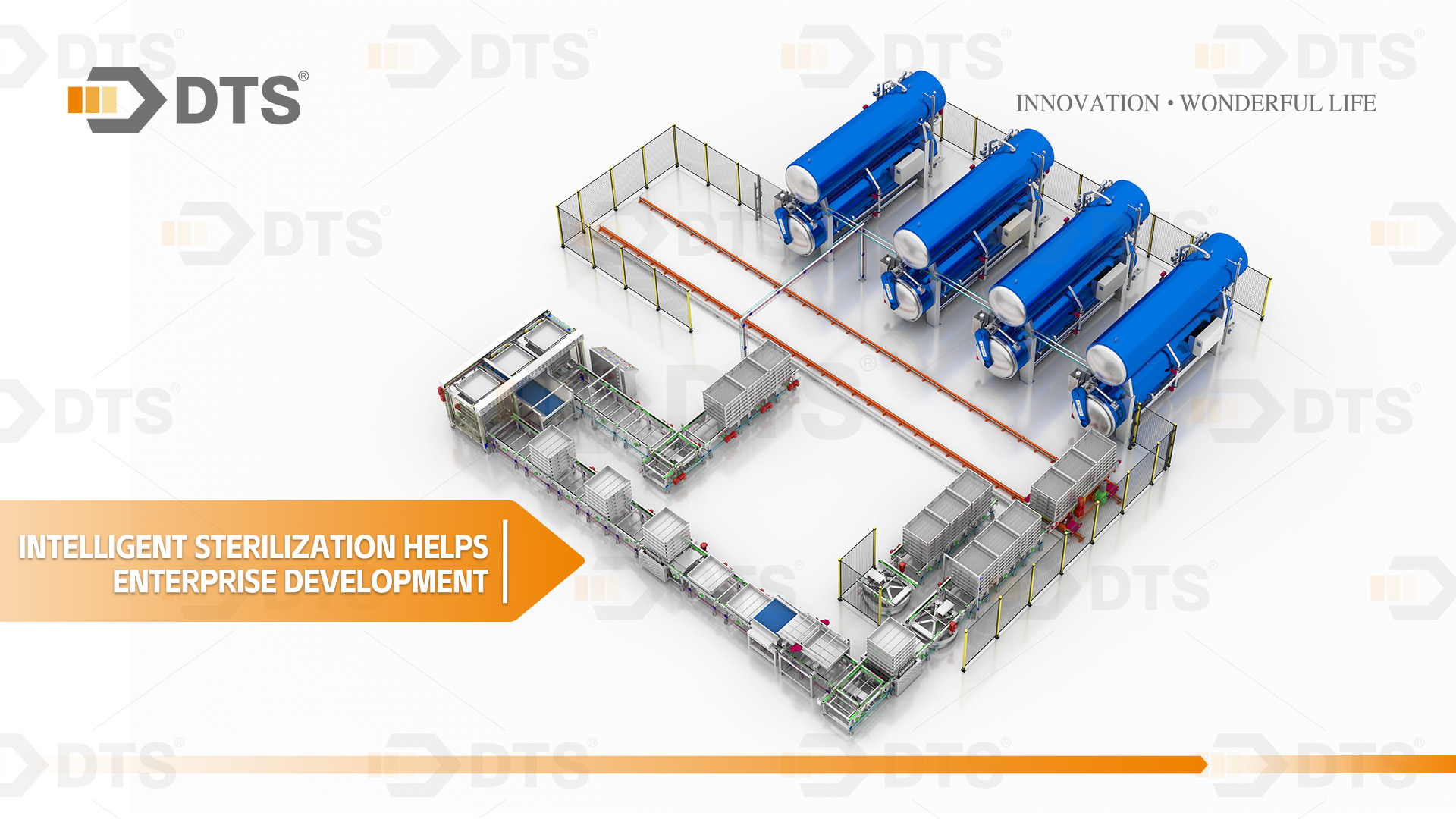

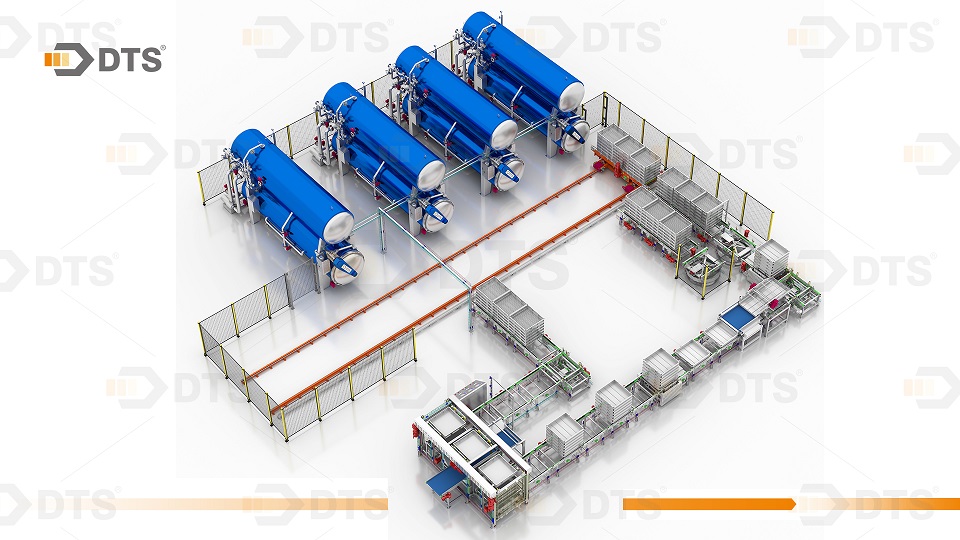

In the process of promoting the transformation from traditional manufacturing to intelligent production, Shandong Dingtaisheng Machinery Technology Co., Ltd. has always been at the forefront of intelligent development and kept pace with the times. Our company closely follows customer needs, flexibly adjusts the layout of production lines, and helps customers build intelligent sterilization workshops, which has won wide praise and favor from the market. At present, our equipment has been successfully exported to 45 countries and regions around the world, and agency and sales offices have been established in many countries. We have established harmonious and stable supply and demand cooperation relationships with more than 130 well-known brands at home and abroad to jointly promote the development of the industry.

First, in terms of production efficiency and quality control, traditional sterilization methods usually require multiple workers to perform manual operations, and when the production intensity is high, it is very easy to cause manual errors, which is not conducive to large-scale production of enterprises, and production costs cannot be effectively controlled.

The intelligent sterilization production line manufactured by our company has achieved seamless integration with the production process through an automated control system, and can automatically control the automatic entry and exit of products in the kettle, cage loading and unloading, and product turnover, thus realizing intelligent production. This not only avoids the possibility of human operational errors caused by manual intervention, eliminates the outflow of unqualified products, helps companies achieve uniform product quality, strictly controls product quality, and improves production efficiency. In our cooperation project with Yinlu, we used the upgrade of the automated sterilization production line to help it reduce the labor cost of 20 people, and on this basis increased production efficiency by 17.93%. For enterprises, the use of intelligent sterilization production lines is very conducive to long-term development.

Secondly, for the improvement of food safety. Food safety is the top priority of food companies, and sterilization is a key step to ensure food safety. The intelligent sterilization production system protects food safety through intelligent adjustment of the heating method, precise pressure control system, and real-time monitoring system. Through the early warning prompts of the real-time monitoring system, we can promptly detect any abnormalities in the production process and take prompt measures to ensure consistent product quality. In addition, the intelligent system can also record the sterilization data of each batch of products, providing strong support for food safety traceability.

Intelligent sterilization production lines can also achieve sustainable development by optimizing the sterilization production process, improving energy utilization. By upgrading the heat recovery system, we can accurately control the heating and cooling process, significantly reduce energy consumption, and achieve the recycling of heat energy.